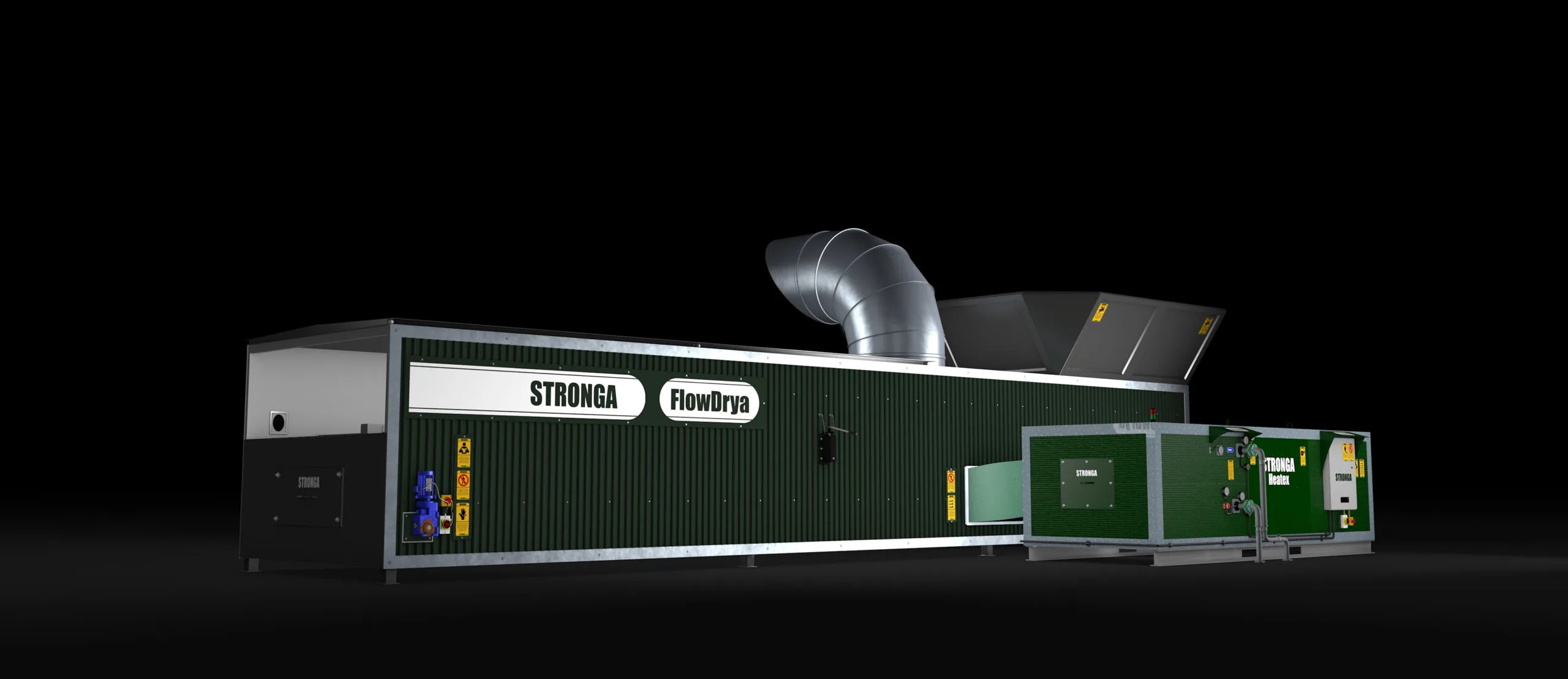

Synonymous with quality & innovation

Well-proven energy & transport systems

Stronga is a family-owned international business whose name is synonymous with quality in the design of innovative transport and energy systems. We have the experience to deliver high quality products and comprehensive business solutions for our customers.

Our aim is to build premium-level machines that have strength, working life and residual values over and above that of other equipment available in the market. We strive for continuous improvement in our long life structures and the services we provide, building trust with customers by adding real value to their businesses.